This operation is purpose to install by-pass line without shutdown at 42” & 32” export line between CPU & NPU export line at badak TRF. Muara Badak is located in east Kalimantan/ borneo. 4-hours traveled distance by vehicles or 2-hours by sea truck from handil (muara jawa).

Before hot-tap campaign some preparation must be under taken,

- Document preparation ie. Hot-tap procedure, job risk assessment, work permit, welding procedure (WPS), interface document/ enter permit to VICO jetty & other procedure related to this acivity

- Inspection : UT (Ultrasonic test) to check actual thickness at welding/ hot tap point, PMI (positive material identification) to check actual composition material

- Site survey : site survey to provide actual dimension before fabrication by-pass spool

- Fabrication : fabrication by-pass spool & flange connection to weldolet

- Other preparation : preparation material, equipment, tool, consumable, vehicle & other

Duration for hot tap is 10 days,

Day-1 : Mobilization equipment & personnel from handil to badak (Equipment transport via mahakam river by LCT & personnel transport by land).

Day-2 : Transfer truck, mobile crane, equipment & material from VICO jetty to Total area

Day-3 : Transfer material, tool & equipment from storage to hot-tap location & install scaffolding

Day-4 : Welding weldolet to 42” - 32 existing pipeline, MPI & install ball valve

Day-5 : Hydrotest of weldolet spool until valve, trial setting crane to position & transfer hot-tap machine from jetty to total storage area

Day-6 : Setting crane to lifting position, mobilization hot-tap machine to location, hot-tap execution, by-pass spool installation & leak test

Day-7 : Blasting & painting

Day-8 : Blasting – painting & demolish scaffolding

Day-9 : Transfer material, tool & equipment to VICO jetty

Day-10 : Transfer material, tool & equipment including truck/ crane to LCT & demobilization personnel

"First day - Time that very exhasuting, work permit for transfer material/ equipment & crane at VICO jetty must be finish before transfer activity. Different rule between Total & ViCo make this job is so long. Tired, our vehicle can't enter Vico location that force me to walk from construction department room to safety room Vico, 1 km distance between each department. Huhh, this day we can't to loading material/ equipment due to time is to limit because work permit just finish at 2.PM.

"Day 2- So many tool/ equipment to un-loading, our team work until night to transfer all material from jetty to temporary storage at Total area.

"Day 3 - Transfer material/ equipment to hot-tap location, setting equipment including trial all equipment and make sure that equipment running well. Scaffolding also must be completed at this day to provide working platform for tommorow welding.

"Day 4 - Fit-up weldolet to existing pipe, this is the critical for the by-pass spool coz by-pass spool already to fabricated. Our fitter must be carefull with this job, Mistake in this stage, by-pass spool must be cut & that mean will be we have additional welding job to suit the fit after Hot-tap campaign. After fit-up is done, next is welding weldolet...dangerous job, welding in existing pipe that still have pressure...better far away with this activity, mistake during welding...."Boooooooom". After welding done, ball valve also must be install so tommorow we can perform hydrotest.

"Day 5 - Setting hydrotest equipment, filling water & pressurize......but some water drops from the gasket during pressurize, that mean we must release pressure & re-tighten the bolt & try to pressurize again until get acceptance hydrotest criteria. Finally, under overcast no more water drops & hydrotest chart also show that the hydrotest is accept.

"Day 6 - 6.AM, we must start earlier coz this is the main job...HOT-TAP, so nervous this morning, first challenge for me, 300 personnel in other site (NPU) must be stop activity only for this campaign because export line must be deprresurize to minimize is in case accident occur during lifting. after all equipment already to setting in place, next is lifting activity for lift hot-tap machine to above valve. Setting the connection & perform leak test. No leak that time, so hot-tap already now. Power pack is already on, open valve & 9.AM start to drill existing pipe.....1.PM, 4 hours duration but hot-tap machine not show if the existing pipe is penetrate by drill bit (normally 1.30 hours to do this job). Our technician decide to retract drill bit/ cutter, the cutter is broken when penetrate the existing pipe. spare is only one, everyone feel panic. Cutter include arbor must be change with the other one, if the spare also broken this campaign must be stop and will be perform in next project & that mean is incident in this campaign. Second chance with spare cutter everyone is worried if this execution if like first drill, but after 1 hour execution hot-tap machine is show if the penetration/ drilling is running well. 1 hours 30 minutes, coupon result from first drilling is taken from hot-tap machine. still have one drilling must be finish before sunset. Without washing time, hot tap machine we lift again to next drilling. Finally in 5.30 PM hot-tap is done, second coupon is from second drill is taken out. Remaining job is lifting by-pass spool & leak test with N2 that we completed finish in 8.PM....."wonderfull night after worried all of the day" completed jobbbbbbbbb

"Day 7 - Blasting-painting, nice job...just open permit & wait painter to do this job, start to demob several personnel.

"Day 8 - Still blasting/ painting activity & in aftenoon start to demolish scaffolding & House Keeping......"Completion Job"

"Day 9 - Transfer material/ equipment from hot-tap location to Vico jetty to demobilization

"Day 10 - Loading material, tool & equipment to LCT & go home.......back to handil

=============================miss this place,=======================

|

| Existing Location |

|

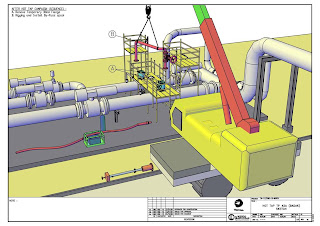

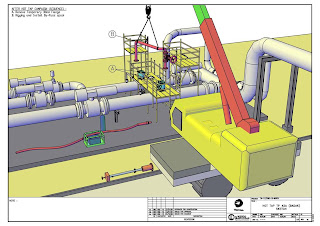

| Lifting valve sketch |

|

| Lifting Hot-Tap machine sketch |

|

| Hot-tap Execution Sketch-1 |

|

| Hot-tap Execution Sketch-2 |

|

| By-Pass Installation sketch |

|

| Lifting Calculation Hot-Tap Machine |

|

| Lifting calculation by-pass spool |

|

| Barack Activity-1 |

|

| Barrack Activity-2 |

|

| Setting Hot-tap -1 |

|

| Hot-Tap execution-1 |

|

| Hot-tap execution-1 |

|

| Hot-tap execution-1 |

|

| Hot-tap execution-1 |

|

| Hot-Tap execution-1 |

|

| Hot-tap execution-1 |

|

| Broken cutter |

|

| Broken cutter |

|

| Hot-tap execution-2 |

|

| Coupon Hot-tap-2 |

|

| Coupon Hot-tap-2 |

|

| Hot-Tap-1 (second execution) |

|

| Hot-Tap-1 (second execution) |

|

| By-Pass spool installation |

|

| By-pass spool installation |

|

| By-pass spool installation |

|

| By-pass spool installation |

|

| After installation by-pass spool |

|

| Leak test with N2 |

|

| Night After leak test |

|

| Night After leak test |

|

| Finish Job (a little party) |

|

| Finish Job (a little party) |

|

| completion job |

|

| completion job |

|

| completion job |

|

| completion job |

|

| completion job |

|

| completion job |

Related Posts by Categories

Kamis, Februari 10, 2011

Kamis, Februari 10, 2011

myone1way

myone1way

Posted in:

Posted in:

1 comments:

Hey..That is cool..Wonderful idea too..And your friend circle is so good..Feeling jealous on you..Thanks for sharing this..

Core Drilling Machine

Posting Komentar